7

Design & Technology –

Systems & Control

7

Education

www.rapidonline.com sales@rapidonline.comSystems & Control

Diameter

Hole size Order code

1+

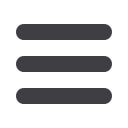

Card Wheels

30mm

4mm 52-2021

£1.72

40mm

4mm 06-0709

£2.61

50mm

4mm 06-0711

£2.89

60mm

4mm 52-2023

£5.02

MDF wheels

25mm

4mm 52-2017

£2.61

40mm

4mm 06-0713

£6.28

50mm

4mm 06-0715

£9.02

54mm

5mm 37-0421

£9.40

70mm

4mm 37-0417

£11.01

74mm

5mm 37-0422

£11.01

071243

RVFM

Card and MDF Wheel Packs

Model wheels made from 2mm thick card or 6mm thick MDF in a range of diameters.

•

Hole diameter 4mm, except for

37-0421

and

37-0422

which are 5mm

•

Supplied in

packs of 100

Order code

37-2228

£9.92

Order code

37-0443

£5.00

RVFM

Medium Polythene

Wheels

39mm diameter polythene wheels

ideal for heavier duty modelling

applications.

•

3mm interference fit centre hole

•

Colours may vary

•

Supplied in

packs of 50

For spiked rubber tyres see order codes

06-0654

and

06-0656

.

RVFM

Model Wheels

Model wheels moulded in robust ABS material with 2.6mm

diameter bores.

•

Supplied in

packs of 4

Wheel size

Order code

1+

10+

25+

37 x 16mm 37-1310

£1.58 £1.37 £1.32

44 x 16mm 37-1315

£1.95 £1.59 £1.37

56 x 16mm 37-1320

£3.11 £2.66 £2.37

031305

Order code

06-0698

£0.221

RVFM

Off-centre Mass

Wheels

These small plastic

mouldings fit directly

onto 2mm motor

spindles, providing

imbalance that is

required for vibrating

mechanisms.

•

Ideal for use in building vibrating ‘bugs’ and robotics

•

Obviate the need to apply any adhesive to ordinary wheels

•

Approx. dimensions: 8mm thick x 20mm diameter

Motor not included. Suitable motors are available separately.

MOQ 5

RVFM

Miniature Pulleys

Miniature pulleys which will

push-fit on to 2mm shafts,

commonly found on miniature

motors.

•

Manufactured in high-

impact polystyrene

•

All sizes include motor

spindle stand-offs

•

Diameter quoted is nominal overall diameter

•

All sizes have 2mm bore

•

Supplied in

packs of 10

Diameter

Order code

1+

8mm

37-0371

£1.42

10mm

37-0373

£1.56

12mm

37-0376

£2.05

18mm

37-0378

£2.30

25mm

37-0381

£2.71

30mm

37-0383

£2.61

300352

RVFM

Propellers

An essential

resource

for your Design & Technology

classroom, these plastic propellers come

in 2 different styles.

•

Fit onto 2mm diameter spindles

•

2-blade: 150mm diameter

•

3-blade: 125mm diameter

MOQ 2

Type

Order code

2+

2-blade 150mm

06-0627

£0.683

3-blade 125mm

06-0629

£0.473

300338

RVFM

Steel Shafts

Steel shafts for use with miniature gears, wheels, motors, etc.

•

2 or 3mm diameter

•

Can be easily cut with a hacksaw

Pack size Shaft size

Order code

1+ 10+

Pk of 50 75 x 2mm dia.

37-0350

£1.49 £1.28

Pk of 50 75 x 3mm dia.

37-0352

£2.11 £1.77

Pk of 25 120 x 3mm dia.

37-0354

£1.54 £1.33

064475

RVFM

120:1 Inline Motor

and Gearbox

This economy motorised gearbox is

fitted with a 3 to 12V DC motor. The

output shaft is 5.5mm diameter and

9mm long with 2 flats. Ratios of 1:120

give final speeds of between 70-

140rpm depending on voltage used.

•

Smooth running

•

3x mounting holes

•

Ideal for small educational projects

including fairgrounds and robots

•

No load current: 70 – 130mA

•

Under load at 6.0V: Motor output turning power is

1.8kgf.cm•

Dimensions 7(L) x 2(W) excluding shaft x 2(W)cm

•

Weight: 30g

Type

Order code

1+

25+ 100+

Motor and gearbox 37-1217

£2.20 £1.90 £1.60

081728

RVFM

Solar Motor Drive

A miniature gearbox and

solar motor which provides a

gear ratio of 27:1 providing

approximately 25 revs. per

minute at 0.5 volts.

•

Final output via 2mm shaft

•

Motor operating range 1.5

to 4.5V

•

Gearbox dimensions 36 x

15mm

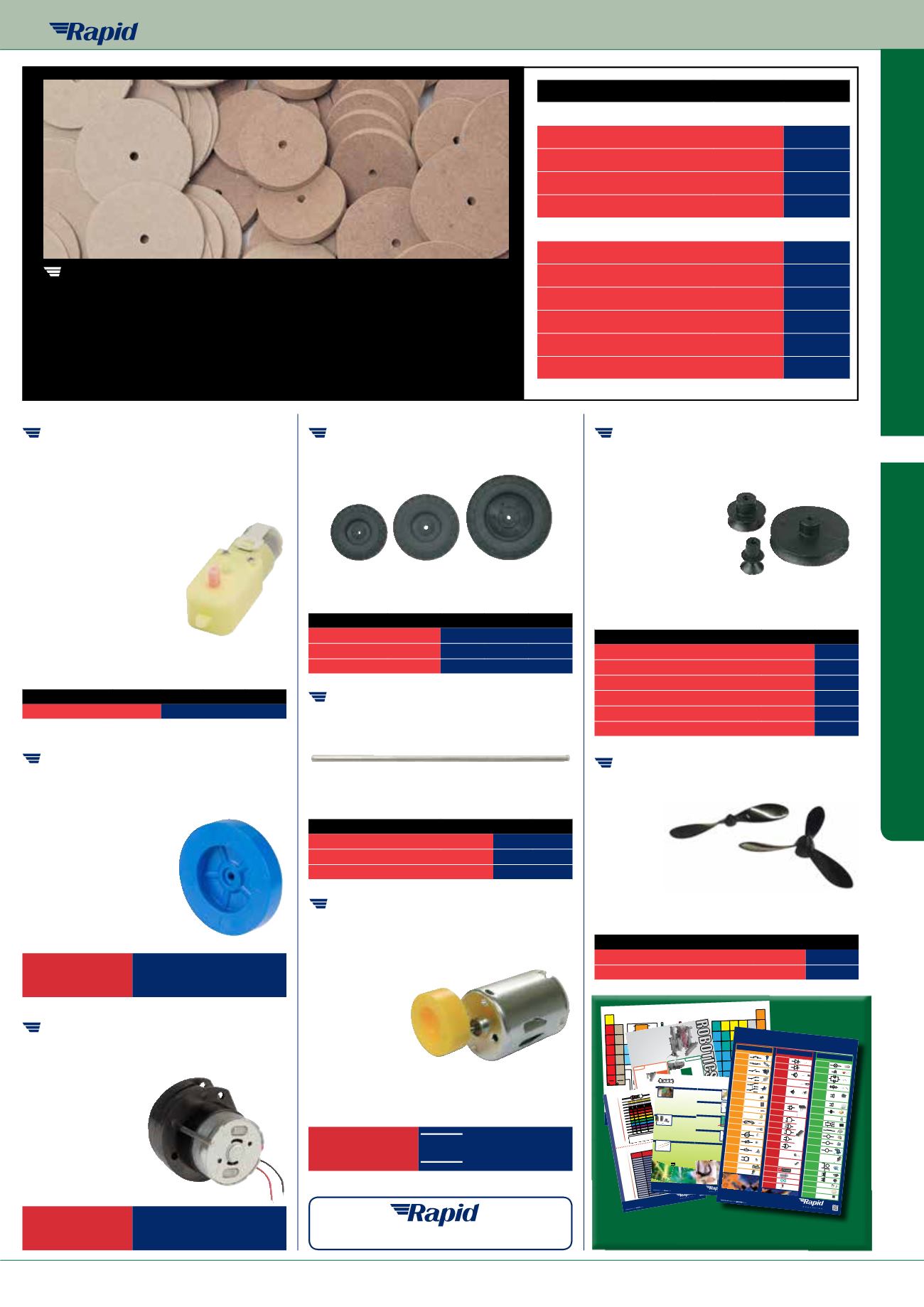

FREE DESIGN & TECHNOLOGY & SCIENCE POSTERS

for your pack

1

1

2

3

4

5

6

7

H

HYDROGEN

1.008

1

18

2

13

14

15

16

17

3

4

5

6

7

8

9

10

11

12

57-71

89-103

Li

LITHIUM

6.941

3

Be

BERYLLIUM

9.012

4

Li

LITHIUM

6.941

3

Be

BERYLLIUM

9.012182

4

Na

SODI

22.99

11

Mg

MAGNESIUM

24.305

12

Li

LITHIUM

6.941

3

Be

BERYLLIUM

9.012182

4

K

POTASSIUM

39.098

19

Ca

CALCIUM

40.078

20

Li

LITHIUM

6.941

3

Be

BERYLLIUM

9.012182

4

Rb

RUBIDIUM

85.468

7

Sr

STRONTIU

87.62

38

Be

BERYLLIUM

9.012182

4

Sc

SCANDIUM

44.956

21

Be

BERYLLIUM

9.012182

4

Y

YTTRIUM

88.906

39

Be

BERYLLIUM

9.012182

4

Ti

TITANIUM

47.867

22

Be

BERYLLIUM

9.012182

4

Zr

ZIRCONIUM

91.224

0

Be

BERYLLIUM

9.012182

4

Hf

HAFNIUM

178.49

72

Rf

RUTHERFORDIUM

261.109

104

Be

BERYLLIUM

9.012182

4

V

VANADIUM

50.942

23

Be

BERYLLIUM

9.012182

4

Nb

NIOBIUM

92.906

41

Be

BERYLLIUM

9.012182

4

Ta

TANTALUM

180.948

73

Db

DUBNIUM

262.114

105

Be

BERYLLIUM

9.012182

4

Cr

CHROMIU

51.996

24

Be

BERYLLIUM

9.012182

4

Mo

MOLYBDENUM

95.96

42

Be

BERYLLIUM

9.012182

4

W

TUNGSTEN

183.84

74

Sg

SEABORGIUM

263.118

106

Be

BERYLLIUM

9.012182

4

F

IRON

55.845

26

Be

BERYLLIUM

9.012182

4

Ru

RUTHENIUM

101.07

4

Be

BERYLLIUM

9.012182

4

Os

OSMIUM

190.23

76

Hs

HASSIUM

265.13

108

Be

BERYLLIUM

9.012182

4

Co

COBALT

58.933

27

Be

BERYLLIUM

9.012182

4

Rh

RHODIUM

102.906

5

Be

BERYLLIUM

9.012182

4

Ir

IRIDIUM

192.217

77

Mt

MEITNERIUM

268.139

109

Be

BERYLLIUM

9.012182

4

Ni

NICKEL

58.693

28

Be

BERYLLIUM

9.012182

4

Pd

PALLADI

106.42

6

Be

BERYLLIUM

9.012182

4

Pt

PLATINUM

195.084

78

Ds

DARMSTADTIUM

281.162

110

Be

BERYLLIUM

9.012182

4

Cu

COPPER

63.546

29

Be

BERYLLIUM

9.012182

4

Ag

SILVER

107.868

7

Be

BERYLLIUM

9.012182

4

Au

GOLD

196.967

79

Rg

ROENTGENIUM

273.154

11

1Be

BERYLLIUM

9.012182

4

Zn

ZINC

65.409

30

Be

BERYLLIUM

9.012182

4

Cd

CADMIUM

112.411

48

Be

BERYLLIUM

9.012182

4

Hg

MERCURY

200.59

80

Cn

COPERNICIUM

(285)

112

Be

BERYLLIUM

9.012182

4

Ga

GALLIUM

69.723

31

Be

BERYLLIUM

9.012182

4

AI

ALUMINIU

26.982

13

Be

BERYLLIUM

9.012182

4

B

BORON

10.811

5

Be

BERYLLIUM

9.012182

4

In

INDIUM

114.818

49

Be

BERYLLIUM

9.012182

4

Tl

THALLIUM

204.383

81

Uut

UNUNTRIUM

(284)

113

Be

BERYLLIUM

9.012182

4

Ge

GERMANIUM

72.63

32

Be

BERYLLIUM

9.012182

4

Si

SILICON

28.086

14

Be

BERYLLIUM

9.012182

4

C

CARBON

12.011

6

Be

BERYLLIUM

9.012182

4

Sn

TIN

118.71

50

Be

BERYLLIUM

9.012182

4

Pb

LEAD

207.2

82

Fl

FLEROVIUM

(289)

114

Be

BERYLLIUM

9.012182

4

As

ARSENIC

74.922

33

Be

BERYLLIUM

9.012182

4

P

PHOSPHORUS

30.974

15

Be

BERYLLIUM

9.012182

4

N

NITROGEN

14.007

7

Be

BERYLLIUM

9.012182

4

Sb

ANTIMONY

121.76

51

Be

BERYLLIUM

9.012182

4

i

BISMUTH

208.98

83

Uup

UNUNPENTIUM

(288)

115

Be

BERYLLIUM

9.012182

4

Se

SELENIU

78.96

34

Be

BERYLLIUM

9.012182

4

S

SULFUR

32.066

16

Be

BERYLLIUM

9.012182

4

O

OXYGEN

15.999

8

Be

BERYLLIUM

9.012182

4

Te

TELLURI

127.6

52

Be

BERYLLIUM

9.012182

4

Po

POLONIUM

208.982

84

Lv

LIVERMORIUM

(293)

116

Be

BERYLLIUM

9.012182

4

Br

BROMINE

79.904

35

Be

BERYLLIUM

9.012182

4

Cl

CHLORINE

35.453

17

Be

BERYLLIUM

9.012182

4

F

FLUORINE

18.998

9

Be

BERYLLIUM

9.012182

4

I

IODINE

126.904

53

Be

BERYLLIUM

9.012182

4

At

ASTATINE

209.987

85

Be

BERYLLIUM

9.012182

4

Kr

KRYPTON

83.798

36

Be

BERYLLIUM

9.012182

4

Ar

ARGON

39.948

18

Be

BERYLLIUM

9.012182

4

Ne

NEON

20.1797

10

He

HELIUM

4.002602

2

Be

BERYLLIUM

9.012182

4

Xe

XENON

131.29

54

Be

BERYLLIUM

9.012182

4

Rn

RADON

222.018

86

Be

BERYLLIUM

9.012182

4

Mn

MANGANESE

54.938

25

Be

BERYLLIUM

9.012182

4

Tc

TECHNETIUM

97.907

3

Be

BERYLLIUM

9.012182

4

Re

RHENIUM

186.207

75

Be

BERYLLIUM

9.012182

4

La

LANTHANUM

138.905

57

Be

BERYLLIUM

9.012182

4

Ac

ACTINIUM

227.028

89

Be

BERYLLIUM

9.012182

4

Ce

CERIUM

140.116

58

Be

BERYLLIUM

9.012182

4

Th

THORIUM

232.038

90

Be

BERYLLIUM

9.012182

4

Pr

PRASEODYMIUM

140.908

59

Be

BERYLLIUM

9.012182

4

Pa

PROTACTINIUM

231.036

91

Be

BERYLLIUM

9.012182

4

Pm

PROMETHIUM

144.913

61

Be

BERYLLIUM

9.012182

4

Np

NEPTUNIU

237.048

93

Be

BERYLLIUM

9.012182

4

Sm

SAMARIU

150.36

62

Be

BERYLLIUM

9.012182

4

Pu

PLUTONIUM

244.064

94

Be

BERYLLIUM

9.012182

4

Eu

EUROPIUM

151.964

63

Be

BERYLLIUM

9.012182

4

Am

AMERICIUM

243.061

95

Be

BERYLLIUM

9.012182

4

Gd

GADOLINIUM

157.25

64

Be

BERYLLIUM

9.012182

4

Cm

CURIUM

247.07

96

Be

BERYLLIUM

9.012182

4

Tb

TERBIUM

158.925

65

Be

BERYLLIUM

9.012182

4

k

BERKELIUM

247.07

97

Be

BERYLLIUM

9.012182

4

Dy

DYSPROSIUM

162.5

66

Be

BERYLLIUM

9.012182

4

Cf

CALIFORNIUM

251.08

98

Be

BERYLLIUM

9.012182

4

Ho

HOLMIUM

164.93

67

Be

BERYLLIUM

9.012182

4

Es

EINSTEINIUM

252.083

99

Be

BERYLLIUM

9.012182

4

Er

ERBIUM

167.259

68

Be

BERYLLIUM

9.012182

4

Fm

FERMIUM

257.095

100

Be

BERYLLIUM

9.012182

4

Tm

THULIUM

168.934

69

Be

BERYLLIUM

9.012182

4

Md

MENDELEVIUM

258.098

101

Be

BERYLLIUM

9.012182

4

Yb

YTTERBI

173.04

70

Be

BERYLLIUM

9.012182

4

No

NOBELIUM

259.101

102

Be

BERYLLIUM

9.012182

4

Lu

LUTETIUM

174.97

71

Be

BERYLLIUM

9.012182

4

Lr

LAWRENCIUM

262.11

103

Be

BERYLLIUM

9.012182

4

Nd

NEODYMIUM

144.24

60

Be

BERYLLIUM

9.012182

4

U

URANIUM

238.029

92

Bh

BOHRIUM

264.125

107

Li

LITHIUM

6.941

3

Be

BERYLLIUM

9.012182

4

Cs

CAESIUM

132.905

55

Ba

BARIUM

137.327

56

Li

LITHIUM

6.941

3

Be

BERYLLIUM

9.012182

4

Fr

FRANCIUM

223.02

87

Ra

RADIUM

226.025

88

Post-transitionmetals

Transitionmetals

Lanthanide

Alkaline earthmetals

Metaloids

Alkalimetals

Other nonmetals

Halogens

Actinide

Noble gases

Radioactive element

Synthetic element

Gas

Liquid

Unknown chemical properties

Xe

XEON

131.293

54

2

8

18

18

8

Atomic

number

Symbol

Atomic

mass

Name

Electrons

per shell

Br

Solid

Ni

Fi

H

Uus

UNUNSEPTIUM

(292)

117

Uuo

UNUNOCTIUM

(294)

118

K

K

L

K

L

M

K

L

M

N

K

L

M

N

O

K

L

M

N

O

P

K

L

M

N

O

P

Q

K

L

M

N

O

P

K

L

M

N

O

P

Q

2

8

18

32

9

2

2

8

18

32

32

9

2

2

8

18

32

8

2

2

8

18

32

32

8

2

2

8

18

31

8

2

2

8

18

32

31

8

2

2

8

18

30

8

2

2

8

18

32

30

8

2

2

8

18

29

8

2

2

8

18

32

29

8

2

2

8

18

28

8

2

2

8

18

32

28

8

2

2

8

18

27

8

2

2

8

18

32

26

9

2

2

8

18

25

9

2

2

8

18

32

25

9

2

2

8

18

25

8

2

2

8

18

32

25

8

2

2

8

18

24

8

2

2

8

18

32

24

8

2

2

8

18

23

8

2

2

8

18

32

22

9

2

2

8

18

22

8

2

2

8

18

32

21

9

2

2

8

18

23

8

2

2

8

18

32

20

9

2

2

8

18

19

9

2

2

8

18

32

18

10

2

2

8

18

18

9

2

2

8

18

32

18

9

2

2

2

8

2

8

8

2

8

18

8

2

8

18

18

8

2

8

18

32

18

8

2

8

18

32

32

18

8

1

2

1

2

8

1

2

8

8

1

2

8

18

8

1

2

8

18

18

8

1

2

8

18

32

18

8

1

2

7

2

8

7

2

8

18

7

2

8

18

18

7

2

8

18

32

18

7

2

8

18

32

32

18

7

2

6

2

8

6

2

8

18

6

2

8

18

18

6

2

8

18

32

18

6

2

8

18

32

32

18

6

2

5

2

8

5

2

8

18

5

2

8

18

18

5

2

8

18

32

18

5

2

8

18

32

32

18

5

2

4

2

8

4

2

8

18

4

2

8

18

18

4

2

8

18

32

18

4

2

8

18

32

32

18

4

2

3

2

8

3

2

8

18

3

2

8

18

18

3

2

8

18

32

18

3

2

8

18

32

32

18

3

2

2

2

8

2

2

8

8

2

2

8

18

8

2

2

8

18

18

8

2

2

8

18

32

18

8

2

2

8

18

2

2

8

18

18

2

2

8

18

32

18

2

2

8

18

32

32

18

2

2

8

18

1

2

8

18

18

1

2

8

18

32

18

1

2

8

18

32

32

17

2

2

8

16

2

2

8

18

18

2

8

18

32

17

1

2

8

18

32

32

17

1

2

8

15

2

2

8

18

16

1

2

8

18

32

15

2

2

8

18

32

32

15

2

2

8

14

2

2

8

18

15

1

2

8

18

32

14

2

2

8

18

32

32

14

2

2

8

13

2

2

8

18

13

2

2

8

18

32

13

2

2

8

18

32

32

13

2

2

8

13

1

2

8

18

13

1

2

8

18

32

12

2

2

8

18

32

32

12

2

2

8

11

2

2

8

18

12

1

2

8

18

32

11

2

2

8

18

32

32

11

2

2

8

10

2

2

8

18

10

2

2

8

9

2

2

8

18

9

2

2

8

18

32

10

2

2

8

18

32

32

10

2

PERIODIC TABLE

www.rapidonline.com/education Rapid Education,Severalls Lane,Colchester,EssexCO4 5JS • Tel:01206 751166 • Fax: 01206751188 • Email: sales@rapidelec.co.uk

M0255 04/14

Hereare justa fewexamplesofhow robotics

canhelp to teach inallareasofSTEM.

Howmanymorecan you thinkof?

STEM www.rapidonline.com Rapid Education, Severalls Lane, Colchester, Essex CO4 5JS • Tel: 01206 751166 • Fax: 01206 751188 • Email: sales@rapidelec.co.uk

M0283

07/14

Robotics in

STEM

Education

92° 43° 45° 98° 51°31°

130mm 125mm 183mm 180mm353mm

280mm

SCIENCE

ENGINEERINGTECHNOLOGY

MATHEMATICS

Energy changes and transfers

Using simplemechanisms to give a larger force at the expense of smaller or slower

movements.

Theword “engineering”comes from the

Latin ingeniummeaning “cleverness”

and

ingeniare

meaning “to devise”.

Educational robotics uses twomain

branches of engineering –mechanical

and electrical/electronic and requires

the application ofmaths, science and

experimentation to devise, test and

analyse solutions.Competition robotics takes this a step further by giving a real problem to solve and an environment in which to test the solutions to the limit.Electronics

A robot requires sensors

to allow it to interactwith

its environment aswell as

motors tomove, solenoids

to control pneumatics and

microcontrollers to process

the data.

Ratios and

Proportions

Robot designs drawn on papermay be at a reduced scale and ideas might be prototyped in smaller sizes to test ideas before building the full scale robot. Gear ratios are used to improve performance ofthe robot –what is the

difference between a3:1

gear ratio and a1:3 gear

ratio? If using a12 tooth

pinion,howmany teeth

will the gear need to have

to achieve a3:1 ratio?

Forces and Friction

In the case of theVEX

RoboticsCompetition and

VEX IQChallenge,mobile

robots are used.For a robot

to bemobile, it needs to

have friction between its drive

wheels and the ground – too

little friction and itwill slip,

toomuch and itwon’t be able to turn.

Balanced forces

- If yourmotor andmechanism can’t

provide the force required to lift aweight,can the

addition of counterbalances or elastic/springs assist?

Programming

The brain of the robot is

amicrocontrollerwhich

processes data received

from the sensors and

controls the actuators

such asmotors and

pneumatics.A program

(code) needs to be

createdwhichwill form

aset of instructio

ns or rulesfor the robot to follow.To

make an efficient robot,

the code needs to be

refined so that instructions

are executed quickly and

accurately.

Probability and

statistics TheVEX competition requires you to form allianceswith other teams – statistics can helpmake decisions aboutwhich teams can complement each other and be the most effective alliance.Electricity

Howmuch current is

required to run themotors

of the robot and how

does this changewith the

loads beingmoved?Does

the battery have enough

capacity to run themotors

for long enough for the

tasks to be completed?

Materials

It is important to select

the correctmaterials for

the job – these could be

selected for a combination

of their strength,weight,

cost and availability.

Robotics provides a practical application formaths and shows how a number of the

fundamentals ofmaths can be used in the realworld.

Geometry Mechanisms on the robotwill require an understanding of geometry to ensure that partsmove correctly. It can also beused to simplify designs

by using geometry to

move other parts of the

robot rather than by

addingmotors.

Capacitance

(picofaradpF)

Capacitance

(nanofaradnF)

Capacitance

(microfaradµF)

Capacitance

Code

10

0.01

100

15

0.015

150

47

0.047

470

82

0.082

820

100

0.1

101

330

0.33

331

470

0.47

0.00047

471

1000

1.0

0.001

102

1500

1.5

0.0015

152

2200

2.2

0.0022

222

4700

4.7

0.0047

472

6800

6.8

0.0068

682

10000

10

0.01103

22000

22

0.022 22347000

47

0.047 473100000

100

0.1 104220000

220

0.22

224470000

470

0.47

474

Resistors

Gold

–

–

÷10

5%

tolerance

Silver

–

–

÷100

10%

tolerance

Brown

1

1

0

1%

tolerance

Red

2

2

00

Orange

3

3

000

Yellow

4

4

0000

Green

5

5

00000

Blue

6

6

000000

Violet

7

7

0000000

Grey

8

8

White

9

9

Black

0

0

4R7 (4.7)5% 1M8 (1,800,000)5% 220K (220,000) 5%1K (1,000)5%

Resistor valus for LEDs

assumingapproximately

20mA is required

Voltage

Value

3V

120

5V

220

9V

470

12V

560

Multiplication factorsand symbols

M

mega

1 000000

(10 )

K

kilo

1 000

(10 )

m

milli

0.001

(10 )

µ

micro

0.000 0

01 (10 )6

3

-3

-6

flaton body is usually cathode (negative)

ResistorColourCodes– carbonfilm

Capacitors

Examples:

103 is10with three zeros–10,000pF or10nF

471 is 47with one zero – 470pFor 0.47nF

Capacitors inparallel

C

TOTAL

=C

1

+C

2

+C

3

etc...

Example:

C

TOTAL

= 47µF+10µF + 4.7µF

C

TOTAL

=61.7µF

Capacitors in series

Example:

so the total capacitance is

1 = 2.99µF

–––––

0.334

1

1 1 1

C

TOTAL

C

1

C

2

C

3

etc…

–––– = – + – + –

1

1

1

1

C

TOTAL

47µF

10µF 4.7µF

––––= –––– + –––– + –––––

C

1

C

2

C

3

47µF

10µF

4.7µF

C

1

47µF10µF4.7µF

C

2

C

3

1 1 1 1 R TOTAL R 1 R 2 R 3 etc… ––––= – + – + –Resistors in series

R

TOTAL

=R

1

+R

2

+R

3

etc...

Example:

R TOTAL = 100K + 47K + 330K R TOTAL = 447K Resistors inparallel Example:so the total resistance is

1 = 2.99K

–––––

0.334

R

1

100K

47K

330K

R

2

R

3

R

1

R

2

R

3

100K

47K

330K

1

1

1

1

R

TOTAL

100K

47K 330K

––––= –––– + ––– + ––––

Capacitance codes give a value in pF.The first two digits are significant

digits and the third digit is

numberof zeros.

www.rapidonline.com Rapid Education, Severalls Lane, Colchester, Essex CO4 5JS • Tel: 01206 751166 • Fax: 01206 751188 • Email: sales@rapidelec.co.uk

M0257 07/141. WHAT ISSOLDERING?

Soldering is the joining together of twometals to give physical

bonding and good electrical conductivity.Solder is a combination of

metals,which are solid at normal room temperatures and become

liquid at between 180 and 230°C.Solder bondswell to various

metals,and extremelywell to copper.

Soldering hasmany uses. It is used primarily to assemble electronic

components such as resistors,capacitors and IC’s onto printed circuit

boards.However, it can also be used to joinwires,metals,and even

manufacture jewellery.

In electronics

LEADFREE

fluxed core

SOLDER

is used.

This consists of approximately 99%Tin and 1% copper depending

on the brand of solder used.Sometimes a small percentage of

silver i added to soften the solder and reduce themelting point

temperature.

FLUX is an aggressive chemical that removes oxides and impurities

from the parts to be soldered.This ensures a good physical and

electrical joint ismade.Fluxes enable good ‘wetting’or ‘tinning’.

Wetting is a term that describes good adhesion of the solder to

the components being soldered.Tinning is a term that describes the applicationof solder to the soldering iron tip,or to a component being prepared for soldering. 2. SOLDERING IRON These are thetoolswhich heat the solder from room temperature to itsmelting point.Amodern basic electrical soldering iron consists of the following:The

HEATINGELEMENT

can be either a resistancewire

wound around a ceramic tube,or a thick film resistance element

printed onto a ceramic base.The element is then insulated ad

placed into ametal tube for strength and protection.This is

then thermally insulated from the handle.The element reaches

temperatures of around 370 to 400°C.

The

SOLDERINGBIT

is a specially shaped piece of copper

platedwith iron and then usually platedwith chrome.Copper is used

for good thermal conductivity. Iron is very resistant to aggressive

solders and fluxes.The bit then fits over or inside the heating

element dependant on the design of the soldering iron.

The

HANDLEANDPOWERCORD

completes the soldering

iron.Various handle styles are available.The power cord is often

insulatedwith PVC.But, this can be damaged andmelt if touched by

a hot soldering iron.Therefore silicone rubber insulated power leads

are extremely popular for long life and electrical safety. 3. IRONSELECTION

Thestrength or power of a soldering iron is usually expressed in

Watts. Irons generally used in electronics are typically in the range

12 to 25Watts.Themost popular irons fr use in schools or for

hobbyist electronics are the 18 and 25-Watt versions.

Itmust be remembered that a 25-Watt ironwill not run hotter

than a 12-Watt iron,but itwill havemore power available to quickly

replace heat drained from the iron during soldering.Therefore, the

bigger the component being soldered, the greater the need for

“quantity of heat”, the higher the power needed.

Most irons are available in a variety of voltages,12V,24V,115V,and

230V are themost popular.You should always use a low voltage iron

where possible,as it ismuch safer.

As your soldering skills improve,youmayworkwith temperature

sensitive devices such as integrated circuits.For these applications a

temperature-controlled soldering iron (TCS) should be used.

For benchwork a soldering stationmay be used.This incorporates

temperature selection,optional digital temperature readout,24V

transformer,an iron holder,and a songe,allwithin a neat bench unit.

4. PREPARATION

1.

If usingmulti-strandedwire such as 7/0.2 equipmentwire, twist

the strands together and tin the end of thewire.

2.

Bend the lead to fit the position on the

PCB.Donot bend too

close to the component body as damag

e to the component

may occur.

3.

If the component is temperature sensitive use a pair of pliers as a

heatsink between the component body and the point to

be soldered.

4.

Tin the sitewhere the component is to be soldered.

5. SOLDERING

1.

Switch on the soldering iron and feed solder to the tip of the

iron as it heats up.

2.

Wipe off excess solder onto a damp sponge

3.

Place the hot iron on the component lead and the PCB pad.

Feed the solder into the far side of the component lead .Solder

will begin to flow around the

lead.Donot use toomuch solder.

4.

Next remove the solder sour

ce followed by the iron.

5.

Do not disturb the component for a few seconds until the solder has solidified. 6. Trim the component leads towithin 1mm of the soldered joint. 6. TAKECARE 1. Plan the component layout. 2. Mount the smallest components first. 3. Try to leave component identificationmarkings visible

4.

Support heat-producing components above the PCBwith

cermic beads.

5.

Keep soldering time to aminimum to reduce the risk of heat

damage to the component.

6.

Bewarof solder bridging across tracks.This could cause a

short circuit.

7.

Ifworkingwith static sensitive components always use awrist

strap connected to an earthing point.

7. CHECKYOURWORK

1.

Are all of the components in place?

2.

Are all of the soldered joints neat and tidy?

3.

Is there toomuch or too little solder on the joint?

4.

Has the solder flowed evenly around the lead?

5.

Is the solder joint nice and shiny?

6.

Are all components inserted the rightway around?

(Check polarity!)

7.

Check for solder bridges.

A INTRODUCTIONTO

SOLDERING

8. ADDITIONAL INFORMATION

In commonwith all tools,a soldering ironwill last longerwith correct care andmaintenance.

1.

Alwayswipe the bit on a damp sponge prior tomaking a soldered joint.Most bench stands incorporate a sponge

for this purpose.

2.

Always apply solder to the bit of an iron as it heats up.Thiswill ensure good tinning and long life of the bit.

3.

A solder bit thatwill notwet can be cleaned by lightly rubbing the bitwith a nylon pad.Ensure the iron is switched

off and do not usewirewoolor emery paper as thiswill remove protective plating and shorten the bit life.

4.

Always keep a hot iron in a bench stand.

5.

Never put a soldering iron into liquid.

6.

Regularly check the cable for burns.Alternatively use an iron that is suppliedwith silicone cablewhich is resistant

to burns from the soldering iron.

It is sometimes necessary to remove a component from a

PCB.Todesolder a componentmelt the solder around

the componentwith a soldering iron.When the solder flo

ws remove themolten solderwith a desolder pump.

Replace the iron in a stand and allow the component to cool for a few seconds.Carefully remove the component

from the holes in the PCB.

TooMuch

TooLittle

JustRight

Good and Bad Joints

(

s

a

www.rapidonline.com Rapid Education, Severalls Lane, Colchester, Essex CO4 5JS • Tel: 01206 751166 • Fax: 01206 751188 • Email: sales@rapidelec.co.uk

M0288 07/14Common components

Input

Process

Output

PTMS

(PushToMakeSwitch)

Diode

+

+V

-V

-

Lamp

M

M

PTBS

(PushToBreakSwitch)

ZenerDiode

+

+V

-V

-

LED

(LightEmittingDiode)

M

M

PST

(SinglePole

SingleThrow)

Transistor

+

+V

-V

-

Bi-coloured LED

M

M

SPDT

(SinglePole

DoubleThrow)

Thyristor

Tri-coloured LED

M

M

DPDT

(DoublePole

DoubleThrow)

FET

(FieldEffectTransistor)

+

+V

-V

-

PCBMounted

Buzzer

M

M

Microswitch

555 IC

TransistorBuzzer

M

M

Keypad

741 ICOpAmp

+

+V

-V

-

UncasedPiezo

M

M

TiltSwitch

SoundGenerator

7Segment

Display

VibrationSwitch

ANDGate

4081 IC

+

+V

-V

-

Relay

M

M

ReedSwitch

ORGate 4071 IC

+

+V

-V

-

Solenoid

M

M

RotarySwitch

NANDGate

4011 IC

+

+V

-V

-

Motor

M

M

LDR

(LightDependent

Resistor)

NORGate

4001 IC

+

+V

-V

-

SolarMotor

M

M

Thermistor

EXORGate

4070 IC

+

+V

-V

-

GearBox

withMotor

M

M

Potentiometer

Melody

Generator

Servo

Microphone

StepperMotor

Driver

StepperMotor

M

M

UltraSonic

Range Finder

PICAXE

Speaker

M

M

Infrared

Receiver

GENIE

MiniatureSpeaker

M

M

Arduino

LCDandDriver

(LiquidCrystalDisplay)

RaspberryPi

MusicalBuzzer

Siren

www.rapidonline.com Rapid Education, Severalls Lane, Colchester, Essex CO4 5JS • Tel: 01206 751166 • Fax: 01206 751188 • Email: sales@rapidelec.co.uk

M0284

07/14

…where price meets quality